Chip manufacturing computing load speeds up 40-60 times: TSMC and Synopsys join forces to promote NVIDIA cuLitho platform deployment

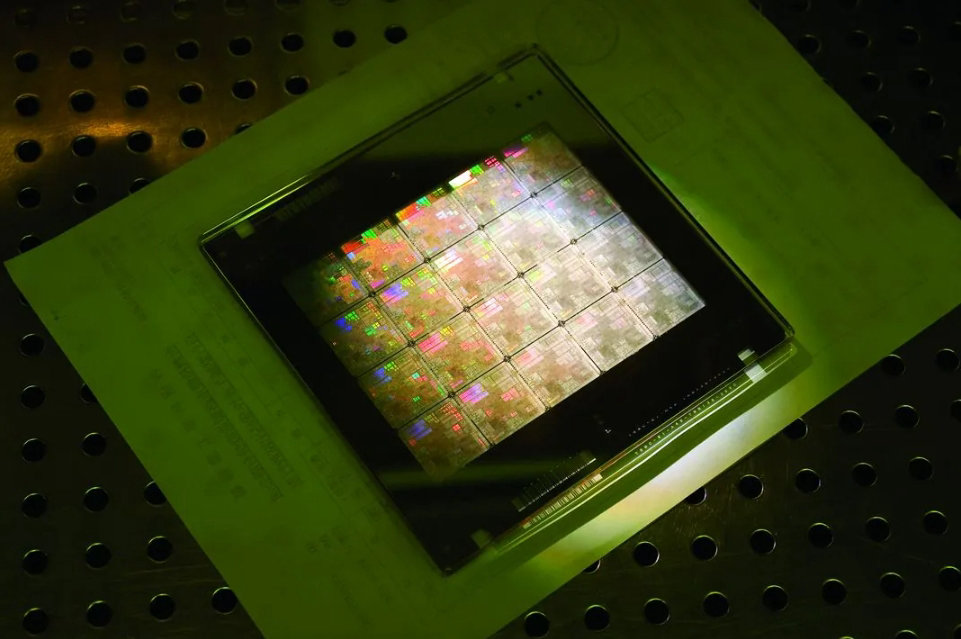

TSMC and Synopsys have decided to integrate NVIDIA's cuLitho computational lithography platform into their software, manufacturing processes and systems to speed up chip manufacturing and support the latest generation of NVIDIA Blackwell architecture GPUs in the future.

Huang Renxun said at the GTC Developer Conference: "Computational lithography technology is the cornerstone of chip manufacturing. cuLitho, which we developed in cooperation with TSMC and Synopsys, applies accelerated computing and generative artificial intelligence, opening up new areas for semiconductor scale."

NVIDIA also launched a new generative artificial intelligence algorithm and enhanced cuLitho, a library for GPU-accelerated computational lithography technology, which significantly improves the semiconductor manufacturing process compared to current CPU-based methods.

Computational lithography is the most intensive workload in the semiconductor manufacturing process, consuming tens of billions of CPU hours every year. One of the key steps in chip production requires 30 million hours of CPU time to calculate a typical mask set, so semiconductor foundries often build large data centers.

Nvidia says 350 Nvidia H100 systems can now replace 40,000 CPU systems, speeding up production times while reducing cost, space and power consumption.

NVIDIA said that the advantages of cuLitho have already been demonstrated in TSMC's production process. The two companies have jointly achieved a 45-fold increase in curve process speed and a nearly 60-fold increase in the traditional Manhattan process.

NVIDIA has developed algorithms applying generative artificial intelligence to further enhance the value of the cuLitho platform. On top of the accelerated processes achieved through cuLitho, the new generative AI workflow is an additional 2x faster.

By applying generative artificial intelligence, it is possible to create a near-perfect inverse mask or inverse solution that takes into account the diffraction of light. The final reticle is then derived through traditional rigorous physical methods, which speeds up the entire optical proximate correction (OPC) process by two times.

Currently, many changes in fab processes require modifications to OPC, increasing the amount of calculations required and creating bottlenecks in the fab development cycle. The accelerated computing and generative artificial intelligence provided by cuLitho alleviates these costs and bottlenecks, allowing factories to allocate available computing power and engineering bandwidth to design more novel solutions as they develop new technologies at 2nm and beyond.